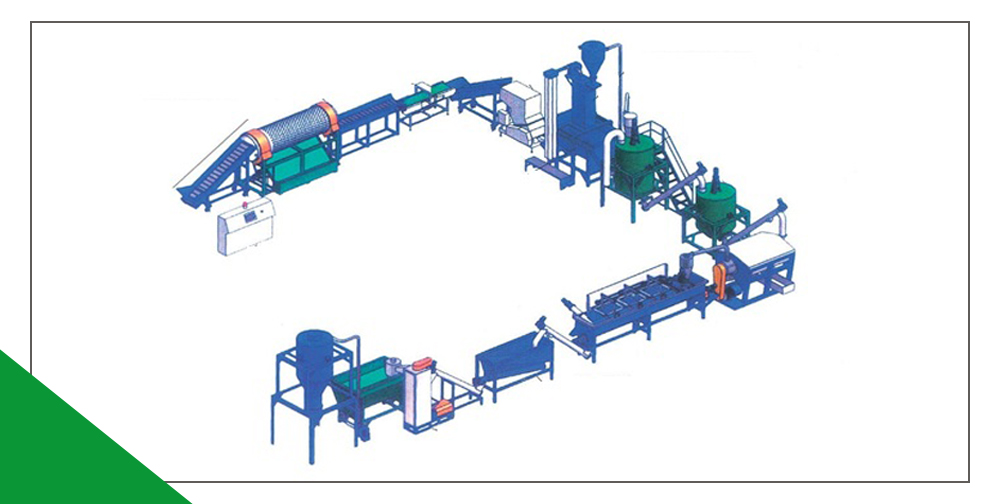

Automatic Pet-Bottle Washing Plant

PET Bottle Washing line is configuration as per contamination in input bottle condition. We provide 500 to 2000 kg/hr Fully automatic plant. Consisting of

- Bale Opener

- Rotary Trommel

- Conveyor Belt

- Label Remover

- Sorting Belt

- Grinder Machine

- Screw Conveyor

- Friction Washer

- Floating Tank

- Hot Wash Tank

- Dryer

- U Tubed

- Blower

- Heater Box

- Cyclone

- Label Separator

- Metal Detector

Complete Turn - Key Plants

- Highly decontaminated flakes

- Low water consumption

- Environment friendly washing process with low chemicals consumption

- Highly automated recycling process with a very poor need of manpower.

RPET - Flakes Perfomances

- PVC < 40 PPM

- PO < 10 PPM

- PAPER < 10 PPM

- GLUE < 10 PPM

- RESIDUAL pH < 10

- HUMIDITY < 0,7%

- COLOR b < 3

- Δ COLOR b < 4

EXTRUSION PLANTS MANUFACTURING PROGRAM FOR THE RE-USE OF PET-FLAKES

- Thermoformed sheets : sheeting lines and/or thermoforming plants

- pellets : by means of pelletizing lines for Bottle-to-bottle process, straps and fibers

- Fibers: directly produced from the flakes.

The pelletizing lines as per point B can perform following outputs :

- 500 Kg/h ± 10%

- 1000 Kg/h ± 10%

- 1250 Kg/h ± 10%

Features

- Extruders with multiple venting

- Excellent maintenance of Viscosity Index and Color

- 500 Kg/h ± 10%

- 1000 Kg/h ± 10%

- 1250 Kg/h ± 10%

Features

- Extruders with multiple venting

- Excellent maintenance of Viscosity Index and Color

- Extruders with multiple venting

- Excellent maintenance of Viscosity Index and Color